Now the design lab is giving a behind the curtain look at how they do it with a new web series.

The SymplBrush looks like a product that shouldn’t exist—an oddly shaped electric toothbrush that brushes your entire mouth at once.

It wouldn’t be out of place on a late-night infomercial or the surrealist sketch comedy show Tim and Eric Awesome Show, Great Job!—the stretchy, U-shaped tray with its multiple bristle heads seems like a gag gift. That the SymplBrush is real and actually works is delightful and bizarre. (And since it cleans at twice the speed of a traditional brush, some would even say it works better.)

The more you look at it, the more sense it makes. We have four different types of teeth, after all. Why shouldn’t we have more brush heads doing the work usually left to one?

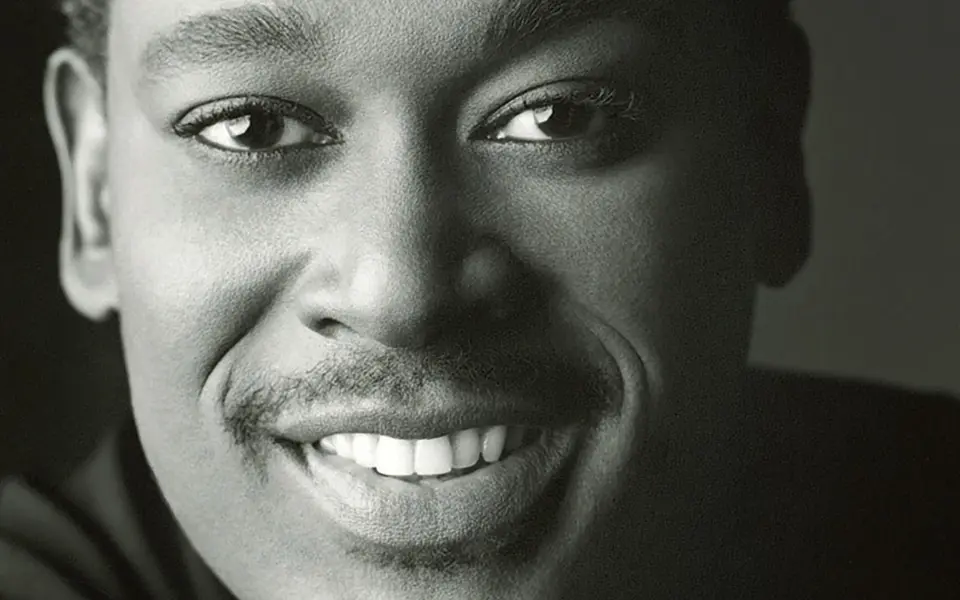

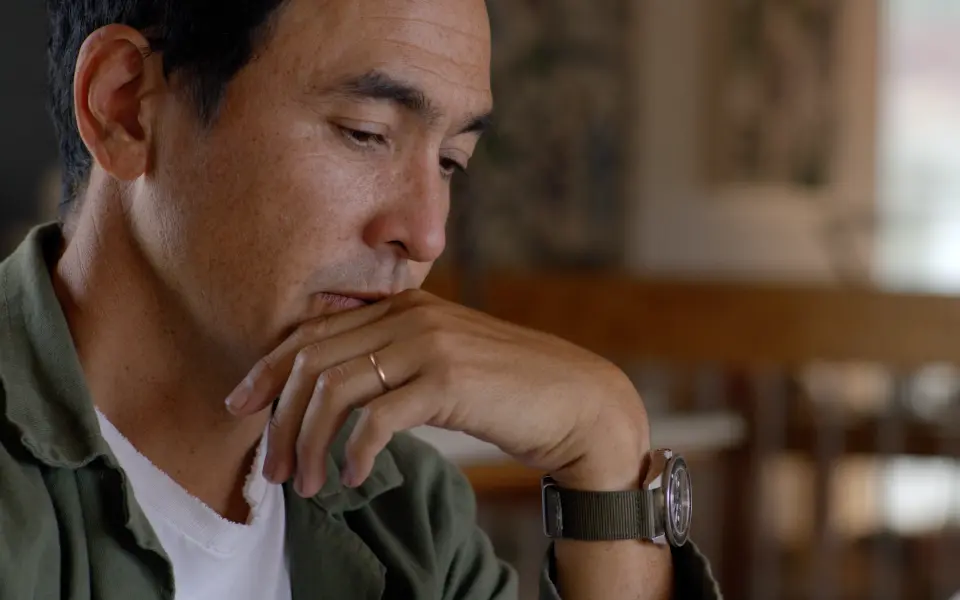

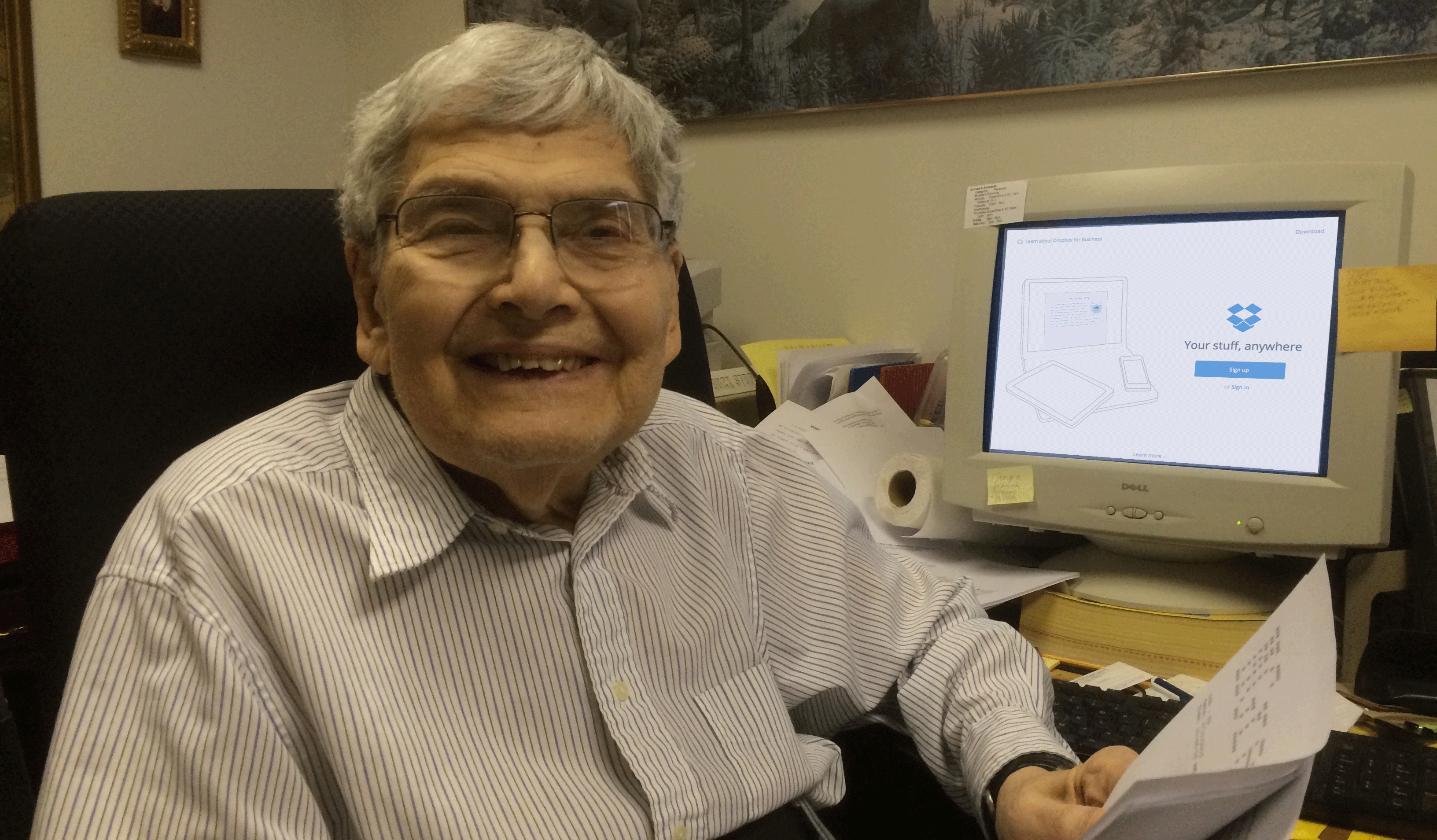

Those are the kinds of epiphanies that Tomorrow Lab®, an award-winning hardware product design studio based in New York City, does best.

“We want people to see our work and say, ‘I’ve never seen anything like this before!’” says co-founder and partner Theodore Ullrich.

By helping entrepreneurs and companies turn their “what ifs?” into real-life products, Tomorrow Lab hopes to make life a little easier for the rest of us, Ullrich says.

Another thing that sets Tomorrow Lab’s work apart? How fast they work. They take ideas and create proof of concepts quickly—like six weeks quickly—and rely on a suite of Dropbox products to make their fast-paced and hybrid style of creating and collaborating possible.

All of their projects have a Dropbox folder, and within that, there are folders separated out by category—electrical engineering, mechanical engineering, and industrial design—that are available to everyone in the company. As the work progresses, Dropbox Transfer lets the team send massive files to clients with a single click, and Dropbox Dash helps Ullrich pull it all together when it’s time to create proposals.

It can be a lot to keep track of—but pulling all of that work together has gotten easier thanks to Dropbox Dash.

To give people a better glimpse into their unique approach to prototyping and design, Tomorrow Lab has even launched a YouTube series called Potentially Genius®—made using Dropbox, too.

“Alongside the actual development work, we’re often educating people as well. At the end of the day, we are a team of problem solvers,” explains Ullrich. “Like, SymplBrush is the most accessible toothbrush ever made. Getting it in the hands of someone with limited mobility is solving that problem.”

Find a team that can do both

Even as a child, Ullrich enjoyed inventing and designing solutions to problems. He once created a system of strings and pulleys to turn off the light switch on the other side of his bedroom. (“Things got more elaborate from there,” he says.)

The spirit of those early prototypes is still alive in Tomorrow Lab today. Products are only as valuable as the problems they solve is one of the company’s values; people should love and feel enriched by the products in their lives is another.

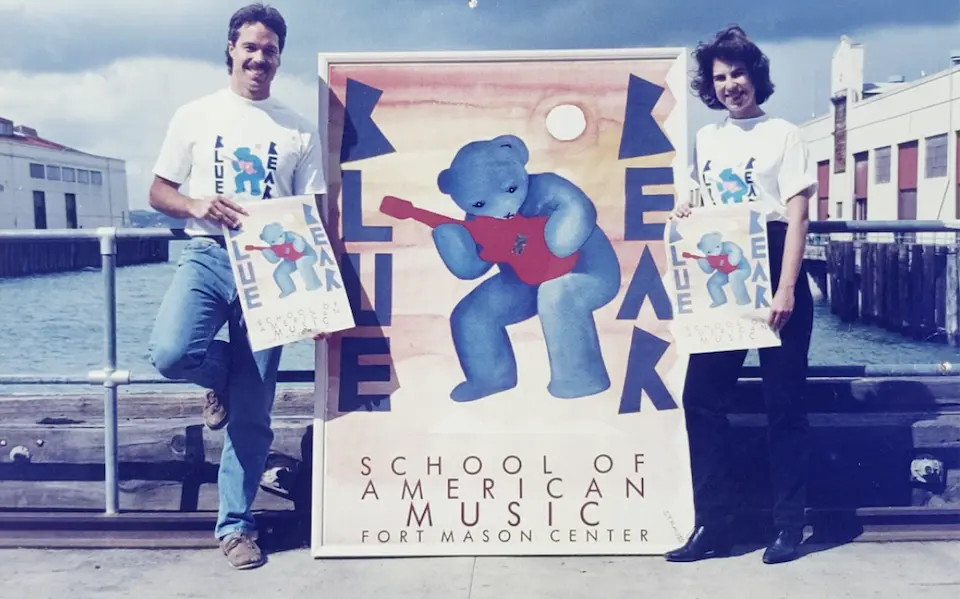

Since Tomorrow Lab opened its doors in 2010, Ullrich, his business partner Pepin Gelardi, and their team of 10 have helped foster industry-shaping innovations like a soil quality sensor that gets valuable data into the hands of farmers and a reproductive preservation service for men using assisted reproductive technologies to start their families. (The company behind the latter recently sold for $100 million.)

Tomorrow Lab started thanks in part to a number of tech developments. Kickstarter launched in 2009, making it easy for entrepreneurs to crowdfund their shower ideas, while the MakerBot 3D printer and DIY electronics platform Arduino were just entering the scene, too.

“All of these stars were aligning where the tools and the equipment and people with my training were able to come together and create products for entrepreneurs,” Ullrich says now.

From there Ullrich and his business partner Gelardi built a team that was reflective of their hybrid backgrounds in design and engineering. Back then, design studios and engineering firms were often separate entities.

“The design firms were coming up with the look of the product, but they wouldn’t have ever dealt with creating a prototype,” Ullrich explains. “And then on the engineering side, it’s the opposite. They would be focused on a lot of problem-solving, but not a lot of questions as far as, ‘Who is this for? How do we fit it into their lives?’”

So Ullrich and Gelardi found folks who could do both—and then some. And by creating a team of “multihyphenate people,” Tomorrow Lab was able to create a four-phase process that leads to holistic innovation: discovery, ideation, prototyping, and presenting.

It can be a lot to keep track of—but pulling all of that work together has gotten easier thanks to Dropbox Dash.

“I have a lot of information that needs to combine: spreadsheets, notes, proposal templates,” he explains. “Being able to open all of those quickly using Stacks is key. It’s sort of replaced the command-spacebar on Mac with something bigger and faster.”

‘Showing the invisible and making it visible’

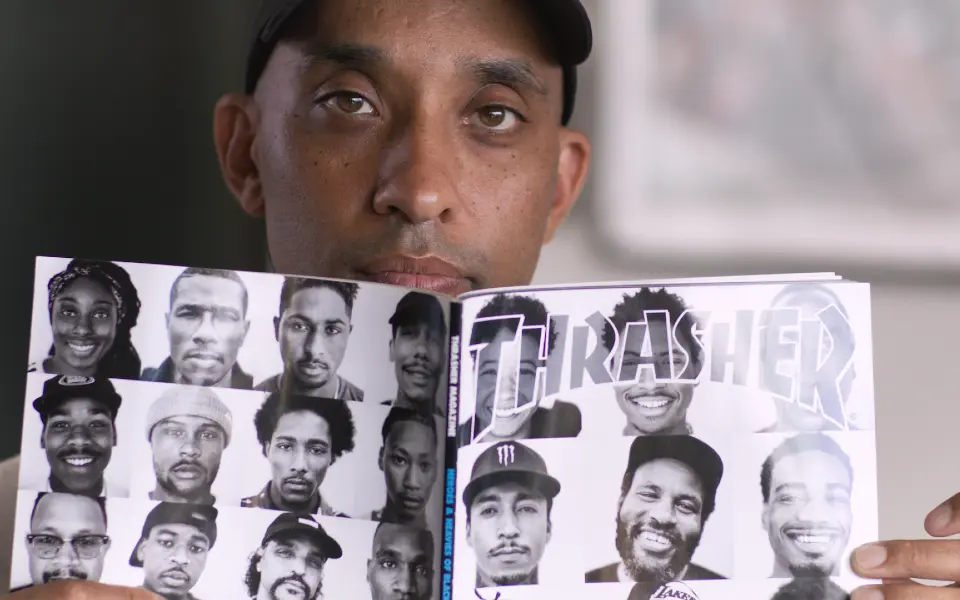

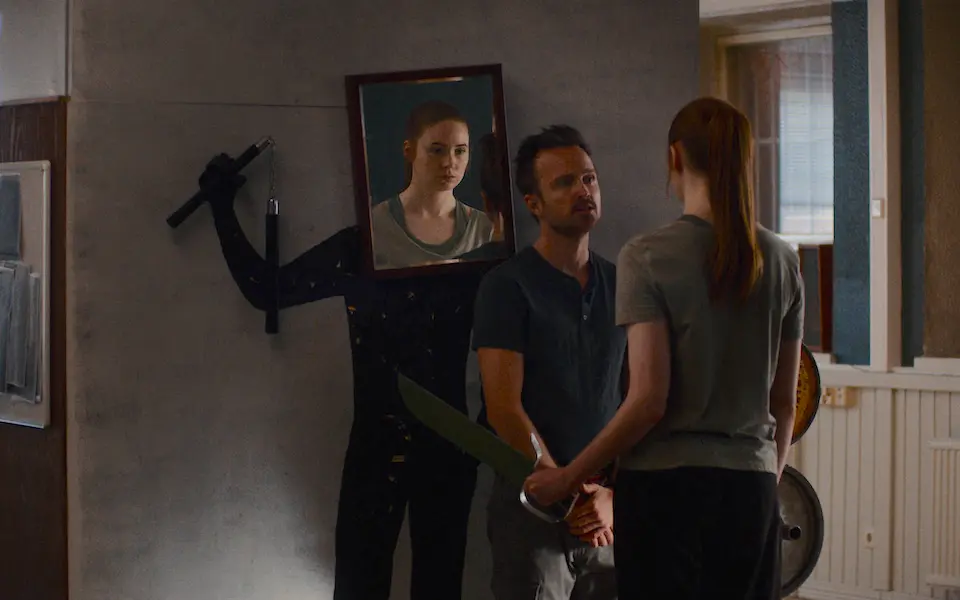

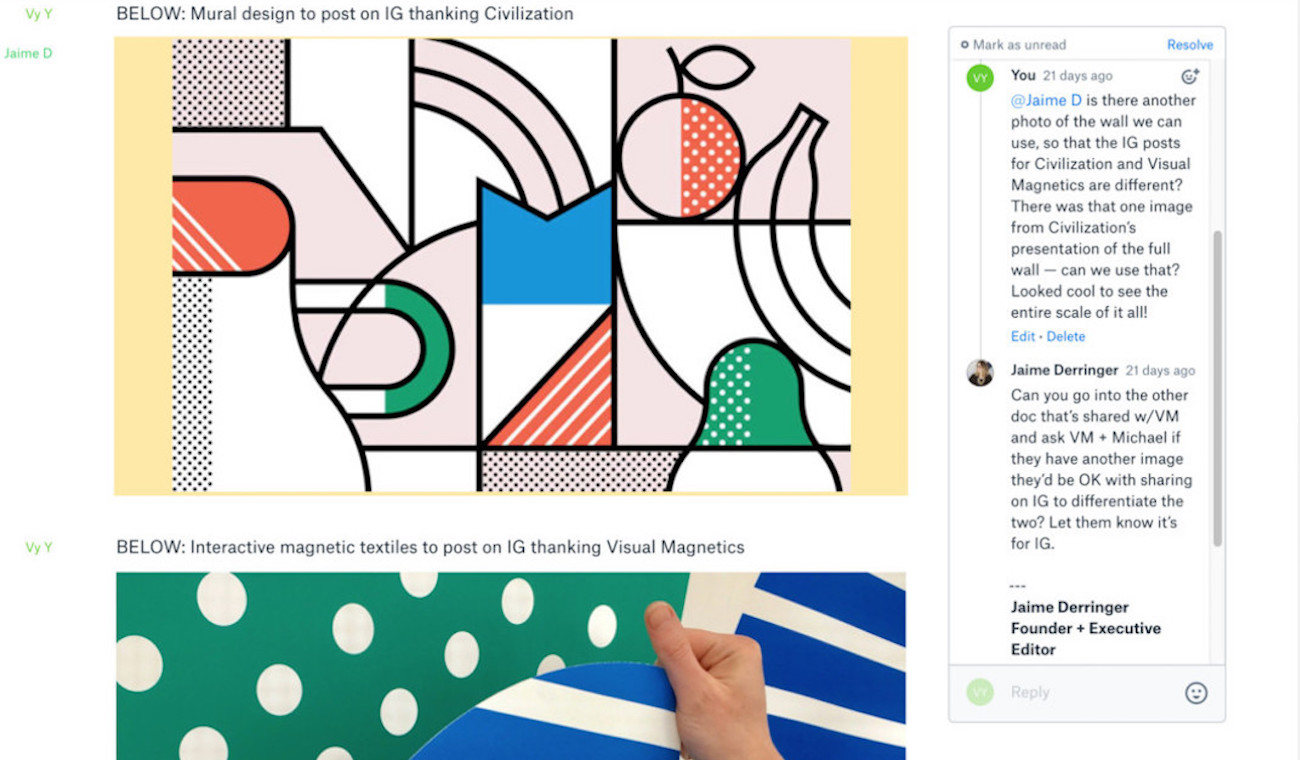

Last year, Tomorrow Lab premiered Potentially Genius, a YouTube series where they help guest experts and companies bring their ideas to life. Created in partnership with electrical component manufacturer Digi-Key, Ullrich hopes each episode can show viewers the possibility of design as a career.

Like any good product, Potentially Genius actually builds on a prior iteration. Inspired by early makers on YouTube, Ullrich suggested that Tomorrow Lab give followers a peek behind the curtain. Part of Tomorrow Lab’s discovery process is breaking up existing products to see what makes them tick. “We might as well record it,” Ullrich said to Gelardi.

The resulting series, The Teardown, was a success. In more than 30 episodes, Ullrich, Gelardi, and different team members broke down a Simplehuman mirror, a fingerprint padlock, and a Dyson vacuum cleaner to discover and explain their inner workings. “Part of showing the invisible and making it visible is demystifying and educating about how that works,” he says.

“The sense that we landed on something genius is more of a gradual unfolding process..."

They step up that premise in Potentially Genius by walking viewers through how they approach building products from beginning to end. (Though, Ullrich is quick to note, these are prototypes without the rigorous testing or polish of the work they do for clients.)

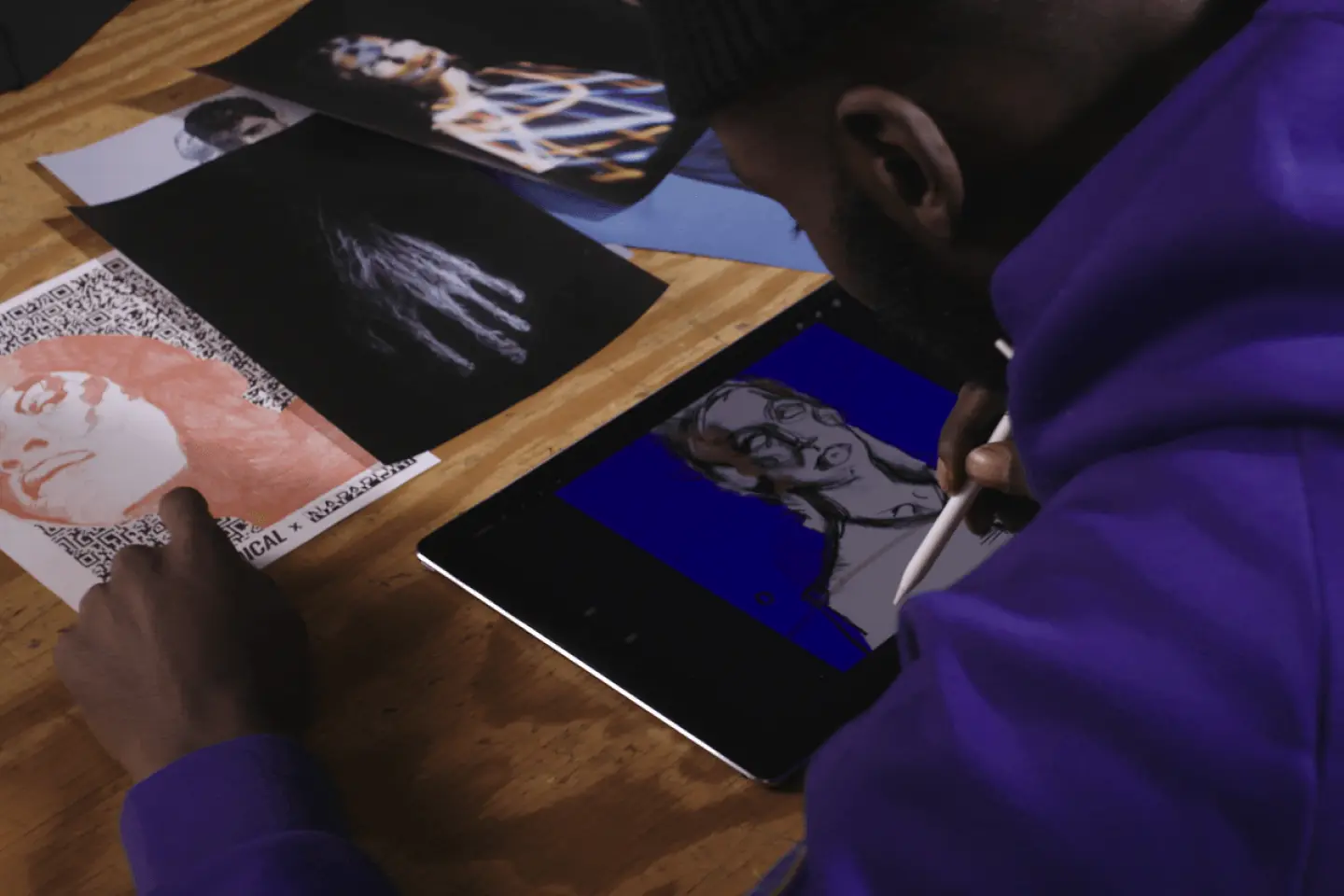

“Much of the series is filmed remotely by our team using their webcams and Sony cameras, so we use Dropbox to upload, organize, and consolidate the footage from various people's computers,” he says. “Our editor and producer then consolidate the footage and edit the episodes. They usually take dozens of hours of footage and reduce it to a 7-8 minute episode.”

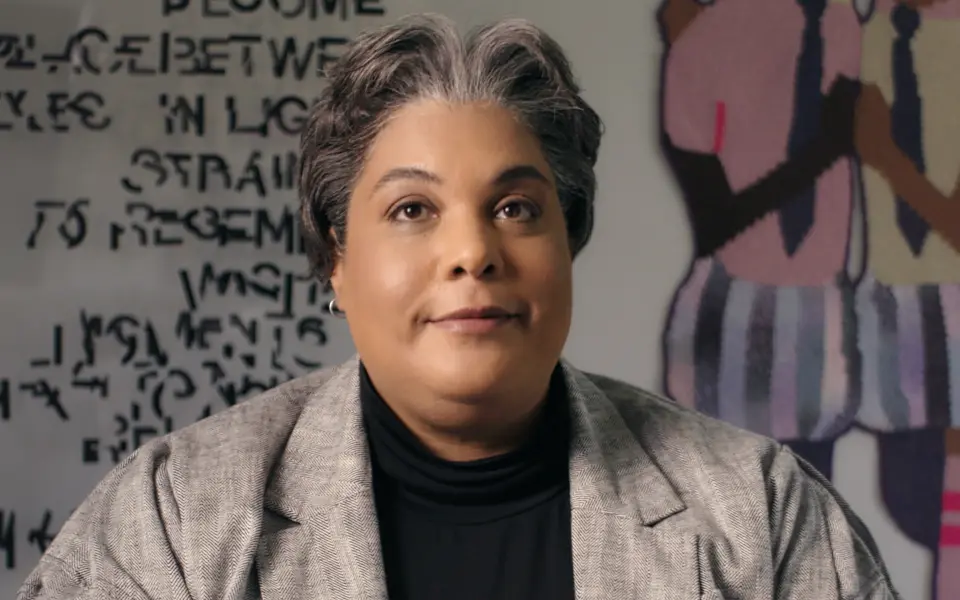

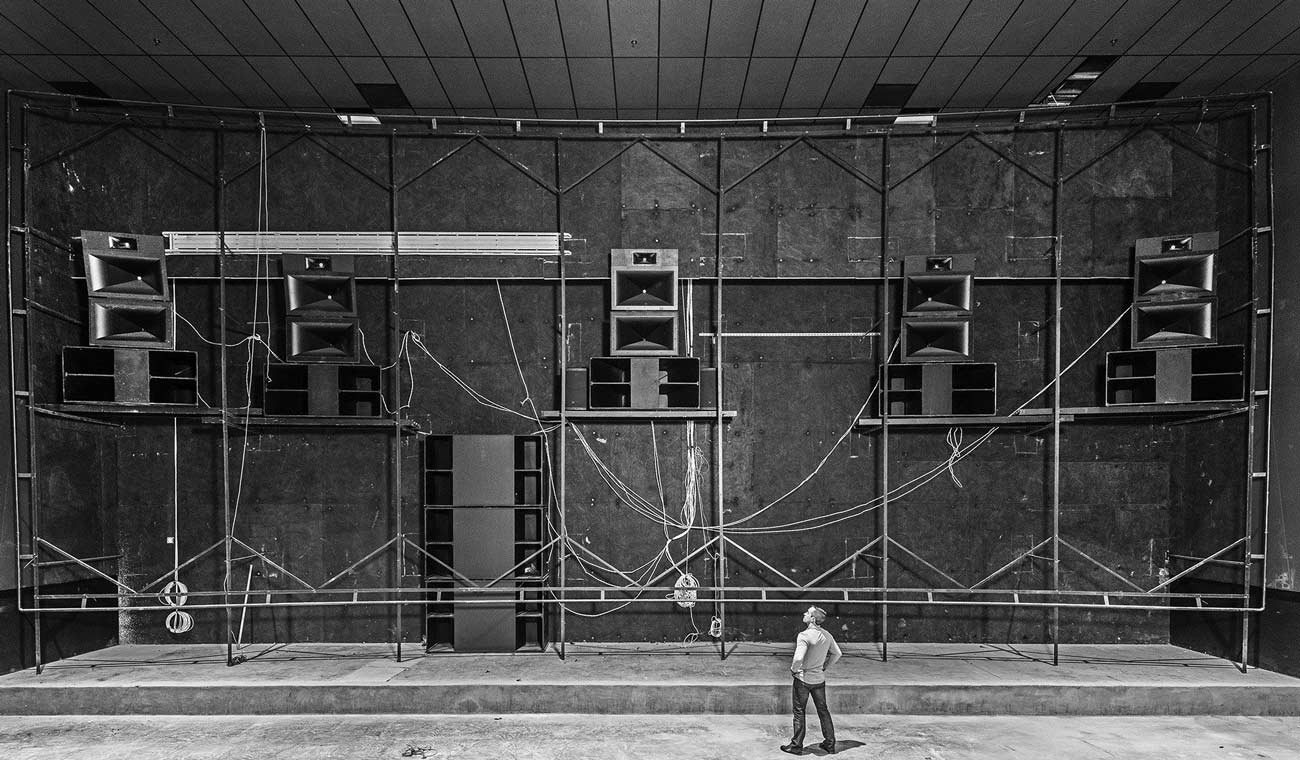

In one of the latest episodes, Dr. Elena Craft of the Environmental Defense Fund asked: “Could we create a device that could live in a public space that brings awareness to the air quality?” says Ullrich. “With the forest fires—and entering a summer that’ll be the hottest ever on record—a product like this is more than conceptual in my mind.”

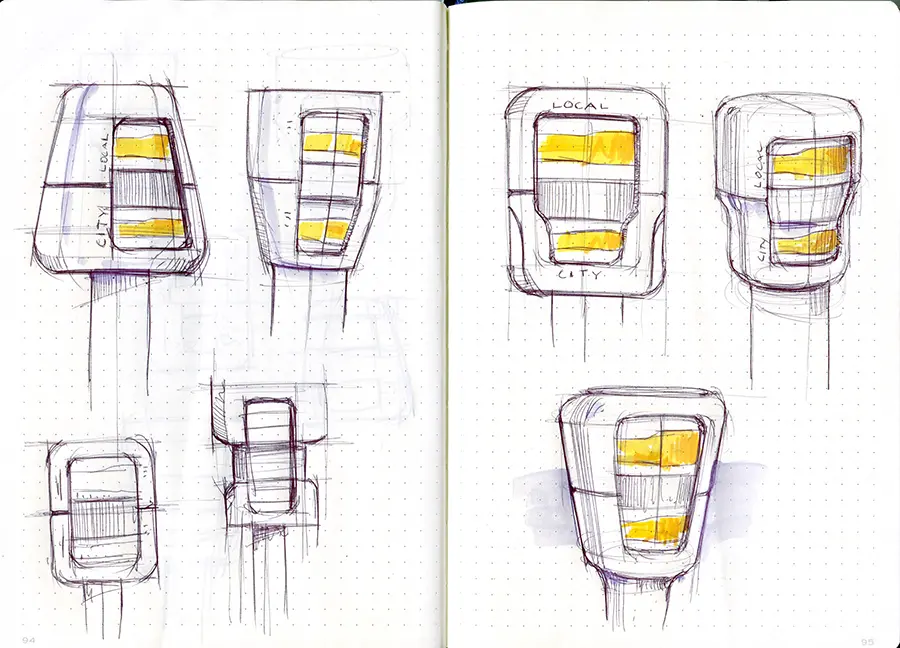

Tasked with building an ozone sensor, Tomorrow Lab launches into their well-oiled discovery, ideation, prototyping, and presentation process.

Sketches are made—an alchemy of design and engineering with what they’ve learned from extensive research and interviews. They land on colored strips that increase in intensity, from green to red, based on the air quality. These would then be attached to 3D-printed rings that move. Powered with a rechargeable battery, outfitted with an air quality sensor, and theoretically connected to a web of other sensors, Tomorrow Lab’s ozone sensor would display the air quality in the place you were standing and the city’s average. And their prototype actually worked, reacting to ozone kicked off by their office’s 3D-printer.

What may seem like a slow and messy process is actually quick and organized, thanks to Tomorrow Lab’s holistic approach and their Dropbox folder structure that makes all the different elements accessible to the entire team. It makes the path to genius-finding a lot more organic.

“The sense that we landed on something genius is more of a gradual unfolding process as we prototype and details are confirmed,” says Ullrich. “We still don't know until we ask the guest at the end if they agree!”

Spoiler alert: Dr. Craft agreed.

.png/_jcr_content/renditions/hero_square%20(2).webp)

.jpg/_jcr_content/renditions/1200x628%20(5).webp)